|

Why Gauge Isn't Always Important. Film thickness is no longer a satisfactory standard for judging overall strength. The development of improved LLDPE resin in the liner industry has completely changed the standard method for selecting the correct can liners. These materials have allowed manufacturers to produce thinner, lighter trash bags which are stronger and more durable than the thicker bags previously made from low density resin. This is why gauge is no longer an effective way to determine liner strength. Instead of stating actual thickness, it is now generally accepted to use terminology such as "Light", "Medium", "Heavy", and "Extra Heavy". (See comparison table.) |

Steps to Choosing the right can liner. 1. How to determine the proper can liner type for your application. There are 2 types of resins commonly used in the manufacture of can liners: (LLD) Linear Low & (HD) High Density. To decide which type you need, answer this question: "Are sharp objects being thrown away?" If yes, you need (LLD) Linear Low Density liners. If no, you need (HD) High Density liners. For Can Size use the instructions below for correct can liner size. |

||||||||||||||||||||||||

Each manufacturer has its own blend formulations, so the proportions of these materials vary from one producer to another. The best way to determine the correct liner is to actually test some suggested samples. |

Definitions Resin- The

basic raw material from which can liners are made. There are 3 types of

resins: Low Density, Linear Low Density, and High Density Polyethylene. Linear

Low Density Polyethylene- This

resin is highly puncture and tear resistant. These properties make this the

best choice for applications where additional strength and stretch are

required. Works well for waste with sharp or jagged edges. High

Density Polyethylene- Liners made from this resin

are generally available in lower gauges, and are more temperature resistant. |

||||||||||||||||||||||||

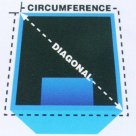

Measuring for Correct Can Liner Size Bag Width: Use 1/2 of the outer circumference of the container. Bag Length: Use the height of the container, plus 1/2 of the diameter of the container bottom, plus 3 inches (for overhang). For square or rectangular containers, use the diagonal of the container bottom, rather than the diameter. |

Low Density Polyethylene- This

is an older resin still used mainly in lower end liners. It has largely been

replaced by Linear Low Density Polyethylene. Post-Consumer and Post-Industrial

Polyethylene This

is made from recycled post-consumer plastics, such as milk jugs and

industrial scraps. These are reprocessed and blended with other types of

resins. Gauge-A

term

used to describe the thickness of a liner. Linear Low density liners are

measured in mils, while High Density liners are generally measured in

microns. Mil-

Measurement based on thousandths of an inch (.000). For example, a .55

mil bag would be 55 thousandths of an inch thick. Common Linear Low density

liners range from .35 to 2.0 mil in thickness. Micron- Based on one hundred thousandths of an inch (.000000). High Density liners usually range from 6 to 24 microns in thickness. |

||||||||||||||||||||||||

| Back to bag order page. Lyn Distributing Home Page | Phone 1-800-366-5022 | ||||||||||||||||||||||||